When you have a floor jack in your home or auto shop, you will be able to lift heavy vehicles and gain access to the components underneath. Hydraulic jacks are quite popular due to their versatile features and the ease of use. These floor jacks work with the help of the hydraulic fluid, which is compressed in the cylinder.

However, just like any other mechanical device, there are instances when you floor jack may fail to work as required. At this point in time, one may be confused as to whether they should repair the floor jack and buy a new one altogether.

In order to make this decision, there are a number of considerations that you should make. One of the most critical elements in being able to understand the different parts of the floor jack. With a clear understanding, you would be able to have a basic idea as to whether you should replace the floor jack and just carry out repairs.

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]

Parts of a Floor Jack:

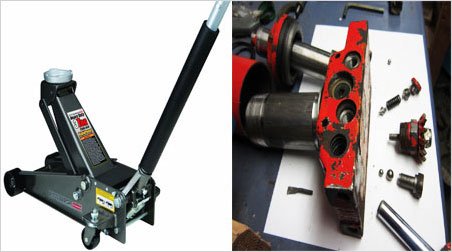

For every floor jack, there are a number of parts that will work together so as to ensure proper functionality. A hydraulic floor jack has the follow parts:

- Pump: When the handle of the floor jack is moved up and down, the pump will facilitate the rising action in the floor jack. It facilitates the compression of the hydraulic fluid.

- Reservoir: This is a tank that is placed inside the floor jack and stores the hydraulic oil, which powers up the hydraulic floor jack.

- Valves: There are a number of valves in a hydraulic jack. The check valve will allow the hydraulic oil to flow from the reservoir to the master cylinder, with a down stroke. The release valve on the other hand is used to release the pressure once you are done using the hydraulic floor jack. It will restore the jack to the resting position.

- Master Cylinder: This is the main tank, where the hydraulic fluid is compressed to trigger the rising action. The oil flows from the reservoir to the master cylinder when you activate the pump.

Anytime when your floor jack fails, these may be some of the parts that you may want to take a keen look at. This will help you in taking a decision as to whether you should repair or replace your floor jack.

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]

Common Problems Of The Floor Jacks

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]The hydraulic floor jack is quite instrumental in various tasks in your garage. Unfortunately, just like with any other equipment, you floor jack may start malfunctioning after a while. There are some elements, which you may realize have stopped working as they used to.

As long as you have been using your floor jack for a while, you will certainly know when it is working as required. There will be a greater advantage when you can recognize the functionality of each part of the floor jack. Being able to detect some problems early will spare you the cost having to buy a new one.

Here are some of the common problems that you can experience with your floor jack. You should be keen on these issues as they may cause serious damages eventually.

Bent Frame

The overall stability of the floor jack heavily relies on the construction of the frame. If the frame of the jack seems to be bent, it may be an indication that the floor jack is succumbing to pressure. If it is just a scratch or marring on the frame, there is nothing serious to worry about.

Should you realize that the floor jack is bent beyond proportion or even has a crack, you should not attempt using it. The floor jack would be a great risk to use, in such a condition.

Faulty Wheels

The wheels and steel casters on floor jacks play a critical role, especially when it comes to the movement of the floor jack. This will also make it easier to position the floor jack under your vehicle. When the wheels are not working, you may have difficulty moving the floor jack around. You can have the wheels checked by a professional, so s to establish the extent of the damage.

Saddle Does Not Rise

When you pump your floor jack and the saddle fails to rise, this means that there a problem with the floor jack. This may be as a result of the hydraulic fluid running low or leaking, or failure of the pump. You should carry out some basic inspection to check if the floor jack is leaking and also check the hydraulic cylinder if the hydraulic oil is too low.

If the oil is low, just refill it to capacity, but if there is a problem with the pump and other components, you should allow a professional technician to handle it. Once the floor jack has been examined, it would be much easier to decide whether it can be repaired or would have to be discarded.

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]

Floor Jack Rebuild or Replacement Recommendation

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]Using a floor jack brings a whole lot of convenience when you have it in your garage. When it develops a problem, you may be torn in between replacing and repairing it. There are a number of factors, which you can take into consideration so as to determine the right course of action to take.

Personal safety is one of the most essential considerations when using a floor jack. You should never support your vehicle with a floor jack that shows signs of wear and tear. This may cause damage to your vehicle and even cause serious injuries or even death.

If you are not sure if you should replace your floor jack or have it fixed, here are some pointers, which will serve as s guide:

Extent of the Damage: The severity of the damage is one of the most critical elements that you should consider. If the damaged is minor, you can have it repaired, by a professional. However, if the damage is extensive, it is advisable to replace the floor jack.

Cost Implication: You should also take into account the amount of money it would cost you to repair the floor jack and compare that with the price of buying a new one.

Availability of Parts: There are some models of floor jacks that have parts, which are hard to find. If you have such a model, then you should consider replacing the floor jack.

Frequency of Use: Ordinarily, repairs take some time and if you run an auto shop, it may not economic sense to wait for the floor jack to be repaired. It would be advisable to buy a new one.

With these factors, you will be able to make a decision as to whether you should repair or replace the floor jack. At the end of it all, pick the option that does not comprise your personal safety.

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]

How To DIY Repairs of the Floor Jack?

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]Depending on the extent of the damage, you can easily be able to repair the floor jack on your own. Here are some common DIY tasks that can help you in repairing the floor jack.

- Clean the Floor Jack

The first step is cleaning the hydraulic floor jack. You should make it a habit to always keep it clean, but more so when conducting repairs. Before opening any compartments, ensure that you have properly cleaned it. This will prevent any dirt or debris from getting into the hydraulic chamber.

- Take off the Plug

When there is dirt in your hydraulic chamber, the fluid is contaminated and this prevents proper function of the floor jack. So it is essential to remove the plug that covers the cylinder.

- Empty the Hydraulic Fluid

Drain out the hydraulic fluid from the hydraulic floor jack. Blow out any debris with compressed air and ensure it is completely clean.

- Refill the Hydraulic Fluid

Once you have cleaned the hydraulic cylinder, refill it with new fluid, using a funnel, so as to avoid spills. Check the manual to ascertain the correct level of the hydraulic fluid that should be poured in.

- Replace the Plug

When you have refilled the oil, you should replace the plug on the cylinder and ensure that it settles in place perfectly. Check to ensure that the plug is clean so that it does not contaminate the new fluid that has been refilled.

After doing all this, the next thing is to test your floor jack to see if the problem has been resolved. When testing the floor jack, do not place any load on it, instead just pump the handle to see if it is rising as expected.

[wpsm_divider top=”15px” bottom=”15px” style=”solid”]

It is important to note that this is a process to replace your hydraulic fluid, which may solve a whole lot of issues. However, if the floor jack has a technical issue, you should consult an experienced specialist, who will determine if you should have it repaired or buy a new one altogether.

Best Floor Jack Guide

Best Floor Jack Guide

hey, i have a floor jack that the handle twists to let down or tighten to pump up. but the handle will not do either, it just moves about an inch either way. any suggestions?